Simnest Aviation is one of the major Hungarian representatives of the international aviation industry. For almost ten years, the company has been producing its in-house developed simulators based on the Airbus A320 aircraft, which are currently used to train future commercial pilots in six countries around the world.

The 1000 square meter main building of their assembly plant, located in Hatvan, a small town near the capital, consists of two halls and a two-storey office building connecting them. The nearly €300 000 project involved insulating 768 square meters of wall surface, 237 square meters of slab and 538 square meters of roof.

Some of the unnecessary windows and doors of the building have been bricked up, and the remaining 55 windows and 5 garage doors have been replaced with insulated ones. In total, the 208 square meters of uninsulated or poorly insulated openings of the building were replaced by 158 square meters of modern insulated windows and doors.

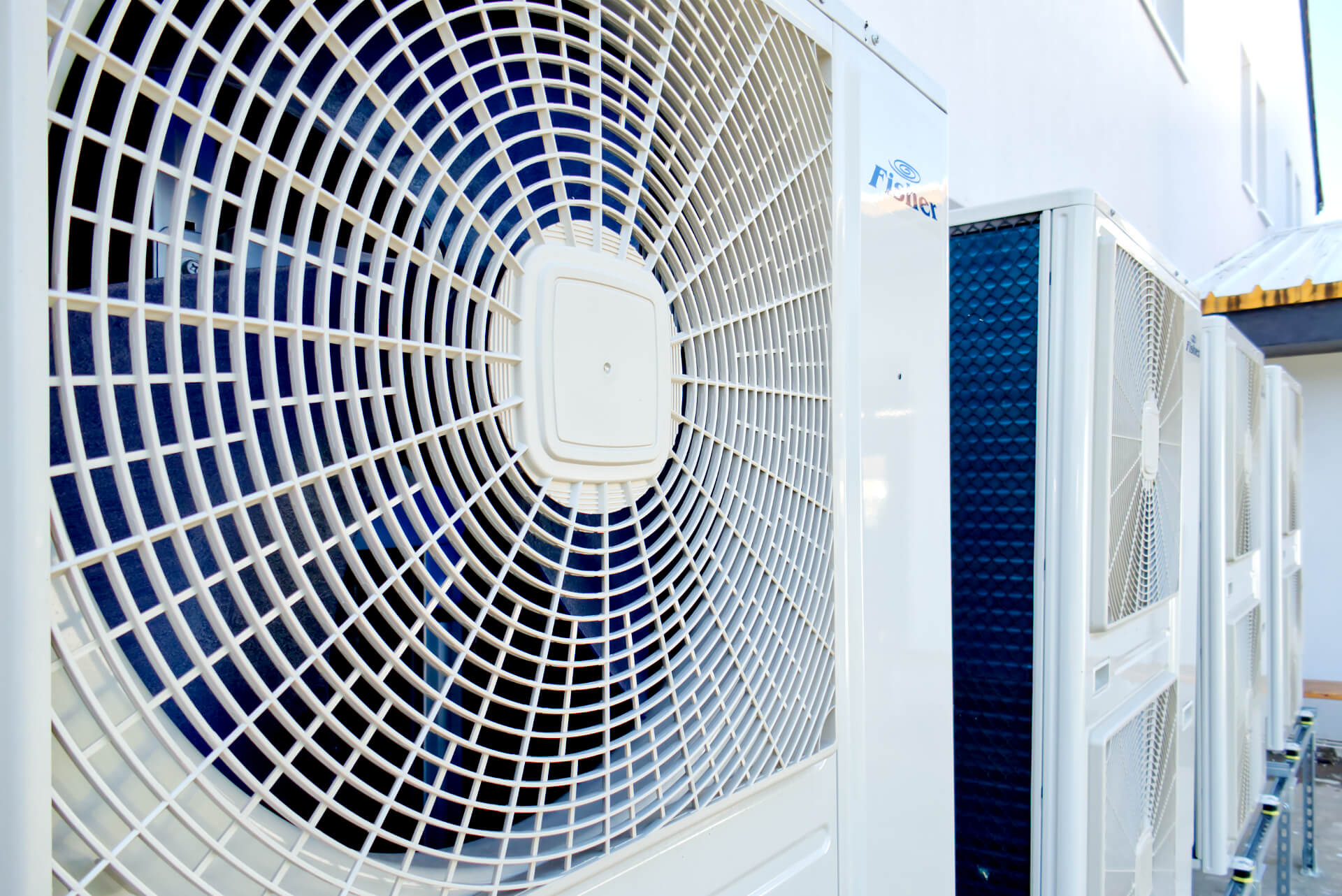

The heating system of the building was also completely renewed, making the plant completely gas-independent. The new heating system is powered by four 4*16 KW air-to-water heat pumps with energy efficiency class A++.

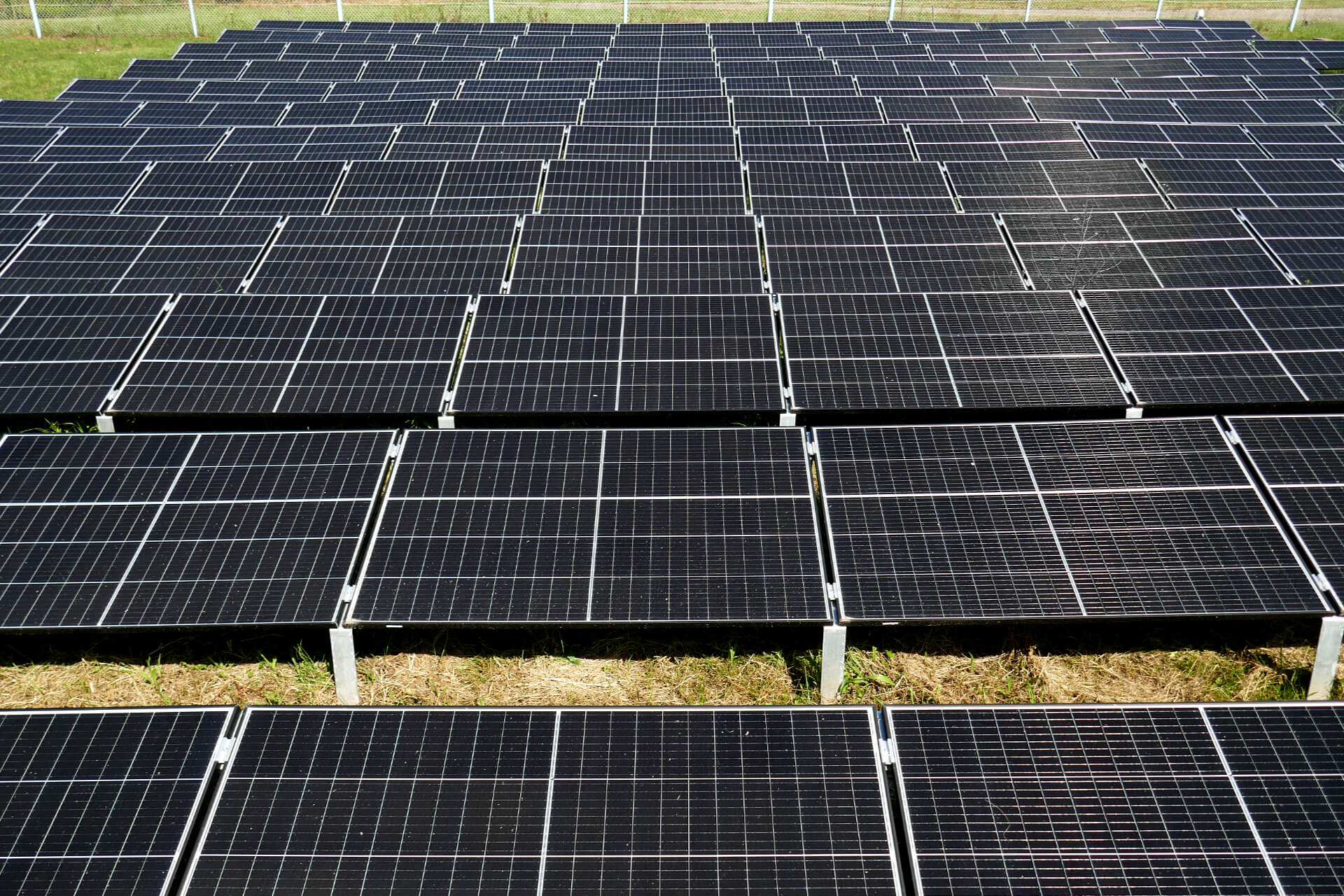

A very significant increase in energy efficiency has been achieved by the installation of a 48.8kWp solar panel system in the courtyard of the building, which can supply both the consumption of the building and building services as well. Thanks to this development the site became self-sufficient in electricity.

“As a simulator manufacturer, we are also aware of the impact of aviation on our living world. Therefore, we cannot be satisfied with providing the best possible training tools for future pilots, we must also contribute to a cleaner and healthier environment for them. We are proud of the fact that as a result of our energy efficiency improvements the annual CO2 emissions of our assembly plant have been reduced from 41.99 to 7,25 tons, and its energy demand has been reduced to almost zero.” - commented Miklós Kacsó, CEO of Simnest Aviation.